|

Wait, isn't it better to put a big wrap around magnet on my oil filter ???

Well if you're comparing an expensive wrap around oil filter magnet to our patented internal magnets, please consider this.

|

|

|

FACT: If you wrap their bulky, heavy Filter Magnet around your cartridge,

you will pull tons of metal out of your oil.

|

|

|

SPOILER ALERT...

|

|

The media paper in your oil filter could have done the same job for free!

|

|

Yikes! You just spent $50 on their fancy looking magnet for nothing.

|

|

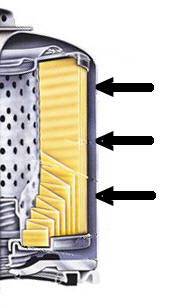

Let's take a look at the center picture, a cut open oil filter

wrapped in an external Filter Magnet type product.

Where is all the loose metal deposited?

On the walls, you say...

Looks right, you say.

|

You are being tricked by these types of photos because they show the larger metal particles that have not reached the oil filter element yet. Remember that if you can see metal it is larger than 50 microns, so all of those loose chips of metal would have been caught by the paper media.

|

Truth is you should never collect metal before it passes into and through the media. What you want to collect with a magnet is any particles that are so small, they go through the media! The ones that are 5, 10 or 15 microns, the ones the SAE documents discussed below say are responsible for 80% of your engines wear and breakdown.

|

A more important issue is engineering! The wrap around products are in direct conflict with the technical design an OE Filter manufacturer builds into their new products.

|

Note in the pictures above that oil flows from the outside to the inside of the filter. Next note the limited space between walls and media paper, it is extremely tight and narrow.

|

Now note where the ragged, rough large metal particles are deposited when external wrapped magnet systems are used. They all end up in nice little rows along the inner wall of the filter's metal shell. Well those walls are factory finished with high tech paint like coatings that seal and smooths the raw steel, so it is a virtually zero friction component.

FACT: The faster and easier the oil flows up the side wall and then into the paper media, the less Horse Power (ie Gasoline) it takes to push the oil through lubrication system.

|

The last thing you or the filter manufacturer wants is a rough surface on the inside of that can, it just does not make good sense on any level. Let the filter do its job of removing larger particles and then let our Ceramic Oil Filter Magnets clean up what the spin-on unit misses...

it's a winning combo! |

For the techies in the group... here is what you are looking for!

SOME IMPORTANT TEST RESULTS

* SAE Technical Papers: 881827, 881825, 952555 & Additional Scientific Studies

Lube oil contamination accounts for seventy to eighty percent of all failures and wear problems. The wear process promoted by oil contamination leads to diminished fuel efficiency, shorter useful oil service life, increased engine down time, reduced component life, loss of engine performance, and an overall increase in operating costs.

Contaminant particles responsible for this damage are in the size range of the dynamic lubricant films separating moving engine component surfaces... 10 microns and smaller. Typically these particles pass through the oil filter and continue to build up in the oil system. By making simultaneous contact with opposing surfaces these harmful particles focus the load onto a small area, degrading the surface and perpetuating a chain-reaction-of-wear.

There are three categories of oil contaminates active in the engine wear process:

1. Solid particles, including wear debris and soot, which damage mechanical components and catalyze lubricant breakdown;

2. Liquid contaminates, including fuel and water, which corrode metals and hinder the functioning of lubricants; and

3. Gaseous contaminants, including acidic combustion products, which corrode component surfaces and degrade the oil.

The predominant harmful impurities in engine oil are metallic particles and metal oxides. Typically there are well over 10,000 contaminant particles per milliliter of lube oil. Furthermore, approximately 90% of these particles are less than 10-microns in size. It's important to note that these particles generate about 3.5-times more wear than particles greater than 10-microns in size. This wear occurs because these particles are the size of, or slightly larger than the dynamic oil films separating opposing surfaces.

Numerous studies have established a number of important points regarding the relationship between lube oil contamination and engine wear.

In the following SAE Paper 881827 substituting a standard 20-30 micron filter with a 10-micron filter resulted in:

1. A reduced concentration of contaminant particles by a factor of 10-15 times;

2. A reduction in the four major wear metals monitored;

3. The filter was capable of operating more than twice the recommended service life; and

4. The lube oil service life to be more than doubled without adverse engine wear or lubricant degradation.

In summary, controlling particle contamination in the 1-10 micron size range retards the chain-reaction-of-wear, resulting in significant reductions in component wear and lubricant breakdown. The beneficial consequences include greater component life and reliability, increased oil change intervals, increased fuel efficiency, and a reduction in overall maintenance costs.

Diesel Component Wear Test on DDA 6V-53T Engine

(Performed by AC Delco Division of General Motors / GM)

Five critical component areas were tested:

1. Upper & Lower rod bearings.

2. Slipper bushings.

3. Compression & oil piston rings.

4. Piston rings.

5. The main bearings.

A. Diesel Engine Wear and Fuel Economy:

A study of twenty-two 6-cylinder diesel engines performed by Fodor & Ling

(affiliated with the Research Institute of Automotive Industry-Budapest and the Rensselaer

Polytechnic Institute)

Conclusion: Control of particles in the 3-10 micron range had the greatest affect in reducing engine wear.

It was found reducing contamination from 0.016% by weight (standard oil filter) to 0.0025% by weight (extended filter / 10 micron control), reduced engine wear by a factor of 14. Most significantly, oil friction was reduced by 2.9% compared to operating with clean oil. This reduction was equated to an increase in fuel economy of about 4%. As a comparison, this significantly exceeds the 0.6 - 0.9% fuel economy gain experienced when converting from SAE 40 to multi grade lube oil.

B. Survey of Diesel Engine Oil Contamination Levels

Samples of 138 engines operating with standard paper filter were compared to 117 engines operating with upgraded 10-micron filters.

Conclusions:

Based on the relationship difference between dynamic oil film and size of wear generating particles, the most important particle size range is 0-10 microns.

1. Diesel engine lube oil contamination causes wear of engine components. Wear of these components leads to loss of performance, increased maintenance and overhaul cost, lower fuel efficiency, and shorter lube oil service life.

2. There is a fundamental relationship between the size of contaminate particles and the thickness of the dynamic oil films developed between moving surfaces of active components. Particles the size of, or smaller than, the oil film thickness cause wear of components. By making simultaneous contact with both surfaces, these particles focus the load onto a small region of the surface, resulting in surface pitting, plowing, and cutting.

3. The average oil film thickness associated with the majority of diesel engine components is in the 7 to 10 micron size domain. This is the size range of the most damaging contaminant particles. In addition, mechanical stress is accentuated during the high-load/thinner oil film phase of the engine cycle. In order to minimize engine wear, emphasis must, therefore, be placed on controlling particles in the 10-micron size domain and smaller.

4. Oil contamination causes component wear and in return, generates more contamination. This is the chain-reaction-of-wear. If uncontrolled, this process results in an enormous number of oil suspended particles. The consequences of uncontrolled chain-reaction-of-wear are:

a) Higher friction, leading to high fuel consumption.

b) Loss of material from sliding and rolling contacts, resulting in misalignment, vibration, and component replacement.

c) Opening of piston dynamic sealing surfaces, leading to loss of compression, further fuel consumption, and contaminant ingestion from the environment.

d) The accumulation of soot and combustion products in the lube oil and the formation of lubricant breakdown varnishes and sludge leading to reduced oil service life.

5. The significance of proliferating particles in the 10-micron range domain is phenomenal. Each grain of contaminant (wear debris, mineral grain, metallic oxide) produces a small but finite amount of friction, abrasive wear, and catalytic oil breakdown. Because of the vast number of harmful particles, the total effect of this multitude is abbreviated oil life, substantially higher engine friction, and propagation of engine wear

6. The benefits of controlling oil cleanliness levels to the order of 100-1000 particles /ml (10 times reduction) are:

a) An 8 to 14 times reduction in engine wear.

b) Up to 2 times increase in oil service life.

c) Up to 2 times increase in filter service life.

d) Up to 5% improvement in fuel economy.

The ultimate benefits are greater diesel engine performance over extended life with lower operating cost.

Independent Laboratory Test by Titan Labs

The subject was a Peterbilt engine (CAT C12) using a Premo LT-30P oil filter system equipped with a 1.2 micron filter. A baseline test was performed at an interval of 15,000 miles as indicated on the Analysis Report dated 4/11/01. Ceramic Oil Filter Magnets were then inserted into the oil filter. After 15,000 miles, the second test was performed on 4/30/01. Please note the dynamic improvement in ferrous particle reduction (in PPM), but also non-ferrous materials/contaminants by the process of heterocoagulation. Final column is percent of change from 1.2 Micron super filter system that costs over $250 and is 25 times better than any standard street vehicle filter.

Tests conducted by:

Titan Laboratories, Denver, CO

Oil analysis report measuring parts per million (PPM), particle size 0.5 microns.

|

Elements

Tested

|

Ferrous*

|

PPM "Before"

Oil Filter Magnet

|

PPM "After"

Oil Filter Magnet

|

Percentage

Reduction

|

| Boron |

Non |

3

|

2

|

33%

|

| Calcium |

Non |

2,929

|

2,870

|

2%

|

| Copper |

Non |

345

|

255

|

26%

|

| Iron |

|

57

|

13

|

77%

|

| Lead |

Non |

5

|

1

|

80%

|

| Magnesium |

Non |

14

|

2

|

86%

|

| Phosphorus |

Non |

1,533

|

1,104

|

28%

|

| Silicon |

Non |

40

|

8

|

80%

|

| Sodium |

Non |

264

|

37

|

86%

|

* IMPORTANT FACT

Even Non Ferrous (Non Magnetic) particulate are pulled in by our Oil Filter Magnets!

The friction reduction improvement caused by removal of Ferrous plus Non Ferrous (the total particulate count)

is why you can improve fuel economy if you include an Oil Filter Magnet in every oil change.

As demonstrated by SAE Technical Papers (listed above), the benefits of oil particle reduction in the 10 micron range are:

An 8 to 14 times reduction in engine wear.

Up to 2 times increase in oil service life.

Up to 2 times increase in filter service life.

Up to 5% improvement in fuel economy.

The ultimate benefits are greater engine performance over extended life with lower operating costs and higher resale value.

GWR Oil Filter Magnets can be added to virtually any oil filter and control particle contamination down to 0.5-microns. This is a 20-times improvement in particle control as compared to the SAE Technical Papers that indicate substantial wear reduction and fuel improvement by control down to only 10 microns.

|